The aircraft structure serves as the foundational framework supporting the overall design of an aircraft. It integrates critical components such as flight controls, hydraulics, and propulsion systems while maintaining structural integrity to withstand diverse aerodynamic forces. This stream emphasizes a comprehensive understanding of the mechanics and physics of structures and solids, with a primary focus on design, analysis, manufacturing, and operation. At the heart of this stream is the quest to understand materials and structures that lead to the creation of lightweight, multifunctional, and adaptable structures capable of withstanding extreme environments. This involves exploring mechanisms operating across various length- and time-scales within structures and materials to achieve the desired effective properties. By adopting a comprehensive approach that integrates theory, computational models, and experiments, we can rigorously analyze material properties, engineer tunable and robust structures, assess structural stability, and conduct health and life-cycle analyses.

The Structures and Materials group within our department has a distinguished history of significant contributions to the growth and evolution of aerospace activities in the country. Our journey began in the 1970s with groundbreaking research in composite structures, providing crucial support to national programs such as the Advanced Light Helicopter (ALH), Light Combat Aircraft (LCA), and HANSA-Light Trainer. The group played a pivotal role in overseeing the use of composites in the LCA, highlighting a key benefit of using carbon fiber composites. Unlike traditional materials such as aluminum or steel, which offer uniform strength and stiffness in all directions, fiber-reinforced composites allow for superior strength and stiffness in specific desired directions. This achievement is made possible through carefully calculated layering and fiber-orientation techniques, resulting in weight reduction, which positively impacts both fuel efficiency and overall aircraft performance. Additionally, our department has been at the forefront of advancements in Non-Destructive Testing methods, particularly in the realms of structural health monitoring and integrity evaluation, with extensive applications in aerospace and defense.

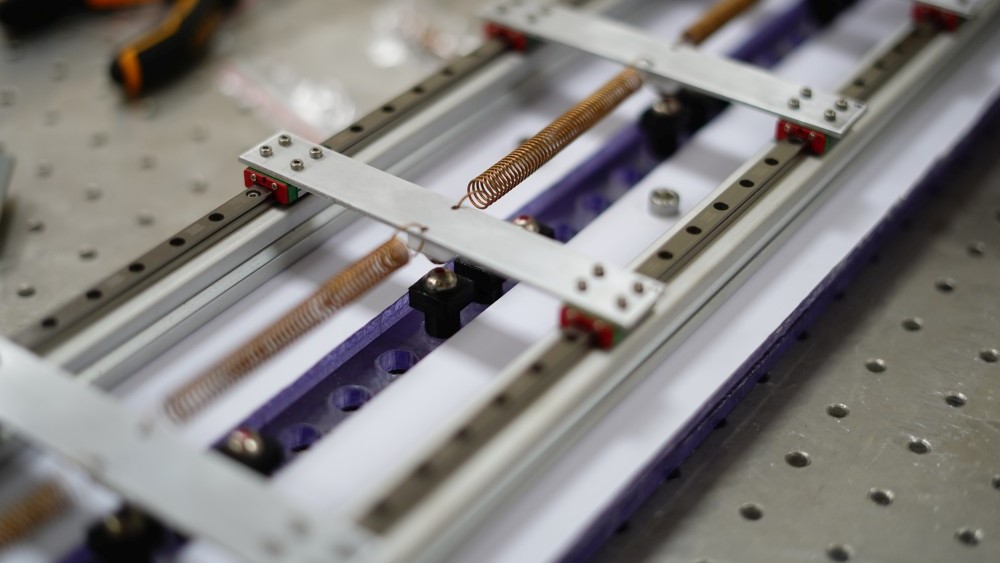

Looking ahead, the group is actively engaged in fundamental research that encompasses various phenomena such as wave propagation, fluid-structure interaction, and multi-physics in advanced materials and lightweight structures. This research contributes to the understanding of vibration isolation, impact mitigation, and the design of novel actuators and sensors, among other applications. Furthermore, it actively contributes to the development of innovative testing methodologies. The group aims to engage in ongoing exploration and collaboration with global industry partners and universities to push the boundaries of aerospace engineering.

Key Focus Areas

- Mechanics and Manufacturing of Composite Materials

- Non-Destructive Testing and Structural Health Monitoring

- Phononic Crystals and Metamaterials

- Functional materials

- Piezoelectric devices

- Smart sensors and actuators

- Fatigue and Damage tolerance of Aircraft Structures

- Aeroelasticity and fluid-structure interaction