Rapid Inspection of Aircraft

Components using Laser Doppler Vibrometry and

Computational Techniques

2009-2014

The objective of this project is to establish rapid inspection of

structural components using Laser Doppler Vibrometry

(LDV) as a new laser-ultrasonic inspection method and develop an integrated

platform. A collaborative research component of this project aims to develop

LDV based signal processing techniques based on guided wave theory by the

project partner Georgia Institute of Technology USA. The platform development

effort aims to address various aspects of inspection processes for various

different types of metallic and composite structural components of aircrafts.

Specific objective is to demonstrate feasibility of the new technology for

application in large area scanning based inspection, associated quantitative

prediction regarding hidden and inaccessible damages using guided wave

propagation theory and computational techniques.

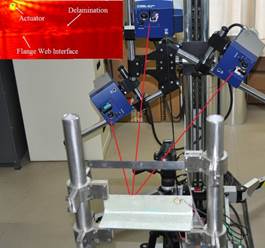

Remote monitoring of structures with laser Doppler

ultrasound; image shows a 3D Laser scanning of a composite structural joint

with hidden damage. Inset shows the hidden damage detected with the help of a

new technique of ultrasound Doppler imaging and computation.

Project

Partners

|

India Indian Institute of Science Bangalore/India |

USA Georgia Institute of Technology Atlanta/USA |

Contact

|

India Prof. D. Roy

Mahapatra Department of

Aerospace Engineering Indian

Institute of Science, Bengaluru/ India Email

droymahapatra@aero.iisc.ernet.in |

USA Prof. S. Hanagud School of

Aerospace Engineering, Georgia

Institute of Technology, Atlanta/USA Email hanagud@aerospace.gatech.edu |

Research

Funding

NPMASS Program, ADA, DRDO

Government of India

Publication

Laser Doppler imaging of delamination in a composite T-joint

with remotely located ultrasonic actuators, G. Kolappan Geetha, D. Roy

Mahapatra, S. Gopalakrishnan, S. Hanagud, Composite

Structures, 147, 197-210 (2016).